Lathe can be divided into horizontal lathe and vertical lathe, the biggest difference lies in the spindle:

(1) The spindle of vertical lathe is vertical, while that of horizontal lathe is horizontal;

(2) When the vertical lathe is working, the weight of the workpiece is directly added to the worktable, and the worktable distributes the weight to the bed. Therefore, the vertical lathe has large load-bearing capacity and good rigidity, which is suitable for processing medium and large-scale workpieces, such as disks, wheel hubs, gear blanks, etc;

(3) The workpiece of horizontal lathe is clamped on the chuck to transfer the load to the spindle, which is borne by the front and rear spindle bearings, so the bearing capacity is small and the rigidity is poor. But horizontal lathe observation and operation are very convenient, so suitable for processing small and medium-sized wheel, and shaft parts.

The spindle design of CNC vertical machine tool adopts short and thick structure. The spindle is divided into three parts, namely working part, transmission part and radial fixed part. In the design process of spindle, in order to ensure the effective transmission of torque, the working part is generally placed at the top, the transmission part is divided into the middle part, and the radial fixed part is at the lowest end.

The spindle drive part of vertical machine tool is basically similar to that of horizontal machine tool. Three phase AC motor is generally used to drive the spindle to drive the workpiece to complete the processing process.

System scheme

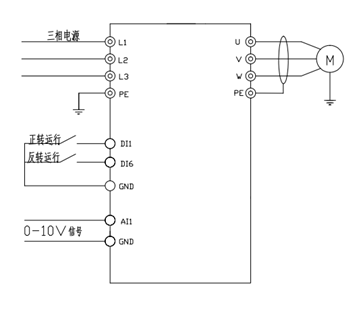

This scheme uses vl6100 series 18.5kw vector general inverter to drive the lathe spindle 15kw motor, V / F control, analog quantity (0 ~ 10V) given frequency, external terminal start stop, fault signal output.

Features of the scheme

(1) Meet the requirements of high productivity, high cutting amount, high stability and high protection of CNC lathe.

(2) Using V / F mode, it has fast dynamic response and high steady speed precision.

(3) It can meet the requirements of high depth and high strength cutting for complex and irregular shape parts, and can stably maintain 150% of torque output under the condition of 0.5Hz ~ 1Hz low frequency.

(4) No need to install brake resistor, acceleration and deceleration time is set to 2 seconds, dead time is set to 0, which can realize fast forward and reverse operation without connection.

(5) Strong anti-interference, through strict EMC comprehensive test, will not cause any interference to the system.

(6) High speed stability accuracy, low speed change rate at low speed, smooth operation.

Field application